We are designing the first educational building, which will

include a laboratory and a classroom.

The classroom is designed for 40 students and a lecturer.

In the lab, there will be a

beekeeping workshop, used during the season to process honey and wax from

beekeepers in the broader area, and also to educate about beekeeping. We aim to

provide beekeepers with quality technology to separate wax from honey, which is

currently not possible in Kashitu. The local community will use the funds from

honey processing to finance the construction of campus buildings.

In Zambia, classrooms often serve multiple purposes.

Therefore, the lab will also function as a classroom for regular teaching

throughout the year.

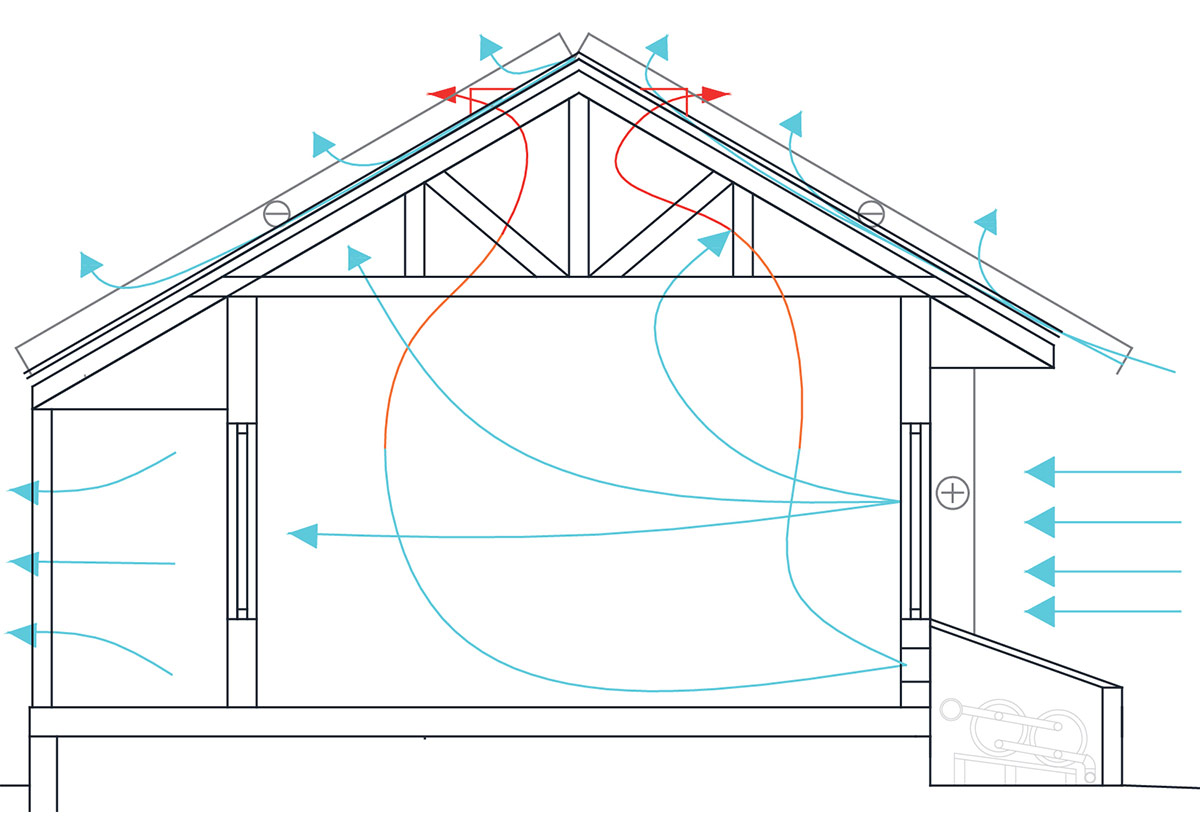

To facilitate a good indoor environment in the classrooms,

it is necessary to establish a backup electricity source. Those who have been

following us know that we have been impacted by electricity outages nearly

every day, which has interrupted our work. This is the reason we are working on

a project for a photovoltaic power plant with a battery storage system,

using the roofs of already built structures and the new planned classroom.

While this won't be enough to power large machines, it will

allow us to use lighter tools during outages. This is crucial since we are only

in Kashitu for a few months of the year.

In the summer of 2024, we opened a sewing and carpentry

workshops. Throughout the year, the local teams have been actively working

and improving their skills. Their products are being sold at the local markets,

and you can also find them at various beneficiary sale events in Czechia or on

our e-shop. In the summer of 2025, we are planning to further broaden the

skillset of the workshop teams and deepen their collaboration. The sewing workshop will be preparing the

beekeeping suits to be used by the beekeepers in the new lab.